|

| March 21, 2017 | Volume 13 Issue 11 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Ford tests out Stratasys 'Infinite Build' 3D-printing machine, focusing on lightweighting and personalization

Ford Motor Company is exploring how large-scale one-piece auto parts, like spoilers, could be printed for prototyping and future production vehicles. It is the first automaker to pilot the Stratasys Infinite Build 3D printer.

Capable of printing automotive parts of practically any shape or length, the Stratasys Infinite Build system could be a breakthrough for vehicle manufacturing -- providing a more efficient, affordable way to create tooling, prototype parts, and components for low-volume vehicles such as Ford Performance products, as well as personalized car parts. The new 3D-printer system is housed at Ford Research and Innovation Center in Dearborn, MI.

VIDEO: As the first automaker to pilot the Stratasys Infinite Build 3D Printer. Ford Motor Co. is exploring how large, one-piece auto parts, like car spoilers, could be printed for prototyping and future production vehicles.

"With Infinite Build technology, we can print large tools, fixtures, and components, making us more nimble in design iterations," says Ellen Lee, Ford technical leader, additive manufacturing research. "We're excited to have early access to Stratasys' new technology to help steer development of large-scale printing for automotive applications and requirements."

The Infinite Build 3D Printer is designed to address the demands of aerospace, automotive, and other industries for large, lightweight thermoplastic parts with repeatable mechanical properties. It features a revolutionary approach to fused deposition modeling (FDM) extrusion that increases throughput and repeatability. The really cool thing here is that the system turns the traditional 3D-printer concept on its side to print on a vertical plane for practically unlimited part size in the build direction (imagine a conveyor belt with a robotic printhead at one end).

Aerospace giant Boeing played an influential role in defining the requirements and specifications for the giant 3D printer when it was in prototype (demonstrator) form.

Part of an emerging technology for manufacturing

Wider adoption of 3D printing has been driven by recent technology advances, new areas of application, and government support, according to Global Industry Analysts. By 2020, the global market for this emerging technology is expected to reach $9.6 billion. As 3D printing becomes increasingly efficient and affordable, companies are employing it for manufacturing applications in everything from aerospace to education to medicine.

Ford is the first automotive company to trial the Stratasys Infinite Build 3D printer, exploring potential applications for future production vehicles, like Ford Performance vehicles or for personalized car parts.

3D printing could bring immense benefits for automotive production, including the ability to produce lighter-weight parts that could lead to greater fuel efficiency. A 3D-printed spoiler, for instance, may weigh less than half its cast-metal counterpart.

The technology is more cost efficient for production of low-volume parts for prototypes and specialized race car components. Additionally, Ford could use 3D printing to make larger tooling and fixtures, along with personalized components.

Ford Motor Company is testing 3D printing of large-scale car parts using the Stratasys Infinite Build 3D printer.

How it works

With 3D printing, specifications for a part are transferred from the computer-aided design program to the printer's computer, which analyzes the design. The device then goes to work, printing one layer of material at a time, then gradually stacking layers into a finished 3D object.

When the Infinite Build system detects the raw material or supply material canister is empty, a robotic arm automatically replaces it with a full canister. This allows the printer to operate unattended for hours -- or days, even.

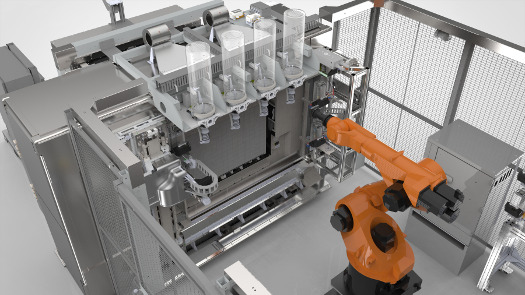

A look at the prototype Stratasys Infinite-Build 3D Demonstrator setup.

Using traditional methods to develop, say, a new intake manifold, an engineer would create a computer model of the part, then have to wait months for prototype tooling to be produced. With 3D-printing technology, Ford can print the intake manifold in a couple of days, at a significant cost reduction.

3D printing is not yet fast enough for high-volume manufacturing, but it is more cost efficient for low-volume production. Additionally, minus the constraints of mass-production processes, 3D-printed parts can often be designed to function more efficiently.

Source: Ford Motor Co.

Published March 2017

Rate this article

View our terms of use and privacy policy